At present, with the artificial cost and energy consumption accounts for the proportion of the cost of production is more and more big, and the effects of environmental pollution on health, so how to improve the PVC pipe extrusion production line of PVC powder raw material feeding level of intelligence, and to reduce the production cost, improve the accuracy of PVC mixing, improve the production environment, has been the target of the manufacturer.

At this stage, most of the pipeline manufacturers are very active in promoting the PVC powder centralized feeding project.However, in terms of the overall effect, the following problems generally exist in the centralized feeding part of the hopper of the extruder:

1 unit extrusion feed hopper of the concentration of PVC raw material conveying, generally USES the chain pipe or spiral type of transport over long distances to many extrusion machines, set high and low on each extruder hopper material level switch, once one a hopper for lack of material, it calls for immediate conveyor feeding operation, so that lead to the conveyor start/stop frequently, greatly affect the stability of the equipment;

2. In addition, once one of the low material level switches fails, the extrusion machine will be shut down. Once the high material level switch fails, the conveyor will be stuck due to continuous operation.

3.regular extruder concentrated feed is generally quantitative parallel transmission, the inside of the extruder hopper of PVC powder in the process of consumption, the change of material level is very big, in the process of the material is easy to cause "flow" and the phenomenon of blanking discontinuous (bridge), cause the extruder screw easy to twist off, more important is after the extrusion molding of plastic products by quantitative feeding inequality problems lead to uneven thickness of serious quality problems.

In view of the problems existing in the centralized conveying of PVC powder, liansu machinery company, after continuous exploration and improvement in recent years, finally provides the user with an effective solution.(16)

The main technical points

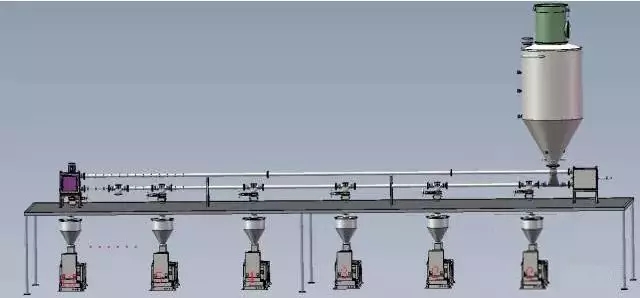

The programmable logic controller is adopted to collect the starting and speed signals of each main motor of the extruder downstream of the whole pipe chain, and then conduct numerical calculation according to the speed signals of each extruder to control the feeding amount of the extruder.

Then calculate the feeding amount required by each production line through feeding amount, and then convert the feeding amount into the speed of conveying pipe chain, so as to adjust the speed of conveying pipe chain in real time.

In other words, when the speed of the downstream main extruder motor increases suddenly or the number of extruders increases, the feeding system will immediately detect the change of speed and the increase of the amount of material used, and increase the feeding speed accordingly, so as to increase the conveying speed of the pipe chain in proportion accordingly.

On the contrary, when the speed of the downstream main extruder motor suddenly decreases or the number of extruders reduces, the feeding system correspondingly reduces the feeding speed and correspondingly reduces the conveying speed of the pipe chain in proportion.

In addition, downstream of the feeder system also read each extruder parameters of current, torque, when extruder super torque alarm, feeder system will automatically shut down the station corresponding pipe extrusion machine chain transmission pipeline discharging mouth, and stop the feeding machine, ensuring that feed extruder shoes no longer increases, so that the decline in extruder output torque, effectively protect the extruder screw, in addition, the flexible powder conveying aspects of long distance, the machine also has a unique full redundancy pressure mechanical design, to ensure that in extreme cases:Even if most of the hopper of the extruder is full, it can also ensure the effective release of the powder pressure generated by the "scraper" during the operation of the pipe chain without leakage.

The specific algorithm

Centralized feeding a total of 13 extruders, in the main extrusion line extruder end of the installation of feeding type control device, using the principle of feeding type feeding, through the monitoring unit time delta t feed volume delta h (that is, the amount of feed extruder), the raw material into the extruder continuous weighing.

Such as when detected the first at the rate of a1 extrusion machine, pipe production chain controller according to the speed of extruder and the proportion of the relationship between K1 calculated at this time the output of extruder for h1, then through feeding type weighing control device, automatic adjust the feeding speed, to feed rate of h1, thus and host machine screw rotation speed negative feedback closed loop control is established.

Due to the central CPU control unit computing speed, scanning cycle is short, so can know a very short unit time delta t control extruder feed h1, once delta h has a slight change, the controller can quickly through the internal PID regulation, automatic adjustment of feeding speed (if delta h larger, increase the speed, and vice versa reduce the speed).Through timely adjustment of feeding machine speed, thus making h1 stable.

In production line speed (line speed can be controlled by the system comes in a tractor of the encoder collection) certain cases, the unit time delta t in the production of products length delta L is also must, therefore, the above device can effectively keep the delta h/delta L (namely the weight of unit length, commonly known as "m" - the weight of the products per meter) constant.

Because: h = р * V

V = S * L

Can be concluded that S = h/(р * L)

That is: S = h/L * (1 / р)

Can be seen by the type: as 1 / р is constant, so as long as the h/L stability, S can keep constant!That is: the wall thickness can maintain uniform.(note: р for material density, volume V for products, S for product cross section, as the length, L h for weight.)

Through the control of stable extrusion amount, the relative constant of "meter weight" of the product can be achieved, so as to guarantee the uniformity of the product wall thickness.Due to the uniformity of wall thickness, the consumption of materials is saved and the quality of products is guaranteed.By analogy, the amount of feed for each extruder is calculated.And then you add them up, and you get the total production is H.Thus, the mixing amount that the pipe chain needs to convey can be obtained. Then, according to the proportional relationship between the conveying speed of the pipe chain and the conveying amount, K0, the velocity V that the pipe chain should operate at this time can be calculated.

The specific formula is as follows:

H = a1 + a2 * * K1, K2...+ a13 * K13

V = H/K0

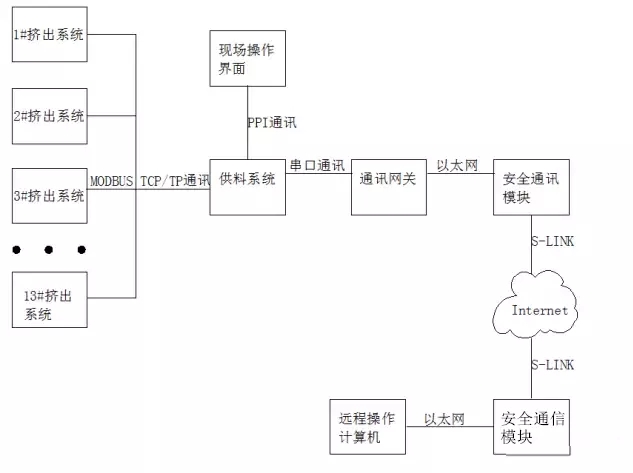

The figure shows the topology diagram of the control implementation of the whole feeding system. The feeding system controller connects 13 downstream extruder systems through Ethernet switch and network cable, and establishes communication through MODBUS TCP/IP communication protocol.

It provides a reliable connection for the whole system control.The feeding system can also establish a remote operation monitoring system through communication gateway and security communication module.Then improve the whole system automation, information level.Users can expand more functions in the future.

Through real-time collection of a series of key data of all downstream extruders, dynamic and uninterrupted operation and timely adjustment of the throughput, and assisted with the mechanical structure of full discharge pressure relief of the extrusion hopper in extreme cases.This can effectively solve a series of problems caused by conventional quantitative and intermittent feeding, such as "punching" and "blocking" of the extruder hopper, easy twisting of the extruder screw, unstable extrusion volume of PVC extruder and high failure rate of the centralized feeding system.